Electrical switches, in general, regulate the flow of current within a circuit and can either start or stop the current flow. There are various types of switches available based on specific needs, such as toggle, pushbutton, limit, joystick, proximity, speed, pressure, temperature, liquid level, and selector switches. This article focuses on selector switches, explaining their functionality and applications.

What is Selector Switch?

A selector switch operates by rotating it either left or right to open or close electrical contacts. Its primary role is to manage devices and switch between at least two circuits. Selector switches are particularly useful for controlling a device’s output. For instance, in an audio system, a selector switch can connect an audio output to multiple speaker sets.

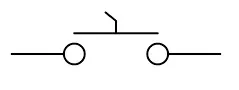

Selector switches are typically sold as complete units, often referred to as terminal blocks. These units include the selector switch actuator, contact block, and fixing collar, making installation straightforward and hassle-free. It is important not to confuse selector switches with rotary knobs or encoders, as selector switches are fully integrated panel-mounted switches.The selector switch symbol is shown below.

How selector switches work

Selector switches function by controlling various current circuits through the rotation of a knob. These switches typically include a simple selector knob on the front panel, along with internal combinations of potential contacts that facilitate their operation.

Construction

Selector switches are made up of several components, including a contact block, holder, operator, and lamp block. Each part plays a specific role in ensuring the switch operates effectively:

- Contact Block: This part houses and protects the electrical contacts.

- Holder: The holder connects the contact block to the rear side of a device.

- Operator: The operator is the switch’s knob, which allows users to control circuits or devices by turning it.

Selector Switch Types

Selector switches come in various forms, differing in shape, material, and functionality to suit specific needs. They are typically made of metal or plastic, with mounting diameters ranging from 16 mm to 30 mm. Below are the main types of selector switches:

Short Handle

This type has a compact handle, making it slightly harder to operate. However, it is cost-effective and widely available.

Long Handle

Featuring an extended handle, this switch is easier to use but comes at a higher price compared to the short-handle version.

Key Operated

Designed for security purposes, this switch includes a removable knob that prevents operation when detached. It features a built-in lock, ensuring only individuals with the corresponding key can activate it, enhancing safety in sensitive applications.

Illuminated

These switches include a built-in lamp for visibility and combine two functions into one operator, saving space. They are affordable and ideal for low-light environments where they help workers identify equipment status (on/off).

Non-Illuminated

Unlike illuminated switches, these lack a lighting element but offer stronger operators. They are often used for controlling machinery across multiple settings and come equipped with contact blocks for easy installation.

2-Position Selector Switch

This type toggles between two electrical circuits and can operate in either a momentary or maintained mode.

3-Position Selector Switch

This switch allows selection between three circuits and is commonly used to activate one of two contact sets or isolate both. It can also operate in momentary or maintained modes.

Selector Switch Circuit Diagram

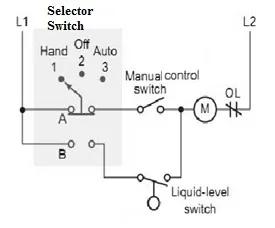

The key distinction between a selector switch and a push-button lies in their operator mechanisms. Unlike a push-button, which is pressed, a selector switch is rotated to open or close the contacts within the connected contact block. Below is an explanation of a three-position selector switch circuit.

The switch positions are adjusted by turning the operator knob either to the left or right. These switches generally have at least two or more selectable positions. They can operate in either a maintained contact position or a momentary position using a spring return mechanism.

Circuit Operation

A three-position selector switch is often used to control different operating modes of devices, such as a pump motor. The circuit functions as follows:

Hand Position: In this mode, the pump motor starts when the manual control switch is closed. The motor can be stopped either by opening the manual control switch or by turning the selector switch to the OFF position.

OFF Position: In this mode, neither the manual control switch nor the liquid level switch affects the pump motor operation.

AUTO Position: When set to AUTO, the liquid level switch manages the pump motor. At a specific liquid level, the switch closes, starting the motor. When another predefined level is reached, the switch opens, stopping the motor.

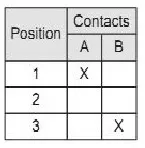

Contact Positions

The contact positions and their corresponding conditions are summarized in a table (not shown here). Contacts are labeled as A and B, while positions are marked as 1, 2, and 3. An “X” in the table indicates that a contact is closed for a particular position.

Which Applications use Selector Switches?

Selector switches are versatile components used across various industries for different purposes. Below are some of the most common applications:

- Automotive: Employed in commercial goods vehicles to manage multiple functions.

- Building and Public Works: Used for interior control systems, such as lighting or HVAC.

- Industrial Controls: Integral to industrial automation and control systems for selecting modes or functions.

- Control System Panel Builders: Incorporated into custom control panels for machinery and equipment.

- Public Spaces: Utilized for managing lighting systems in areas like parks or public buildings.

- Medical Equipment: Applied in medical devices to control specific operational settings.

- Home Automation: Found in smart home devices to switch between various modes or settings.

These applications highlight the adaptability of selector switches in diverse environments, making them essential components in both industrial and consumer systems.