Ever wondered about the key differences between rotary and selector switches?

Rotary switches offer multiple positions and complex configurations, while selector switches provide simpler on/off or limited-position control.

Understanding these distinctions is crucial for choosing the right switch for your electrical project. Let’s explore their unique features and applications in detail.

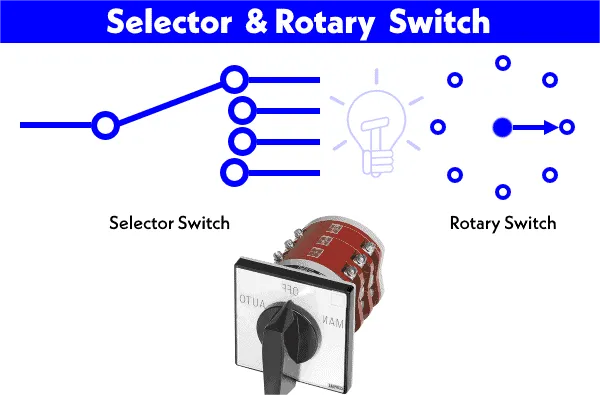

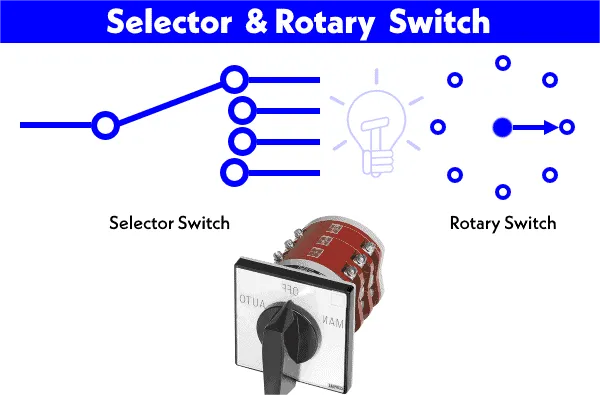

What is a Rotary Switch

A rotary switch is an electromechanical device operated by rotation. It consists of a spindle or rotor with a contact arm that connects to multiple terminals arranged in a circle. Rotary switches are designed for applications requiring more than two positions, such as multi-speed fans or radios with multiple channels.

These switches offer enhanced versatility, allowing users to select from multiple circuit configurations with a single control. They provide precise control through distinct, detented positions and are known for their robust construction, making them suitable for industrial and heavy-duty applications.

Rotary switches come in various types, including shorting, non-shorting, and multi-deck configurations. They can be designed with different numbers of poles and throws to accommodate complex switching requirements. Their compact and space-saving design makes them ideal for applications where space is limited.

What is a Selector Switch

A selector switch is an electromechanical device that controls electrical circuits by rotating a handle or knob. It typically offers two or three positions, allowing users to select between different circuit configurations or operational modes.

Selector switches come in various types, including illuminated and non-illuminated versions. They are designed as complete units, comprising an actuator, contact block, and fixing collar for easy installation.

These switches find applications in industrial control panels, automation systems, and equipment control. Common configurations include MAN-OFF-AUTO switches, which allow users to choose between manual and automatic operation modes.

Selector switches differ from push buttons in their mechanism. While push buttons use a plate to actuate contact plungers simultaneously, selector switches employ a rotating cam with ridges and flats to actuate plungers independently.

The compact design of selector switches makes them ideal for applications requiring multiple switching positions in limited space. They offer clear visual feedback of the selected position, enhancing user-friendliness in complex control systems.

Comparing Rotary and Selector Switches

Number of Positions

- Rotary Switches: Offer a wide variety of positions, often upwards of 10 or more. This versatility allows for complex circuit configurations and multiple setting options.

- Selector Switches: In contrast, typically have 2 or 3 positions. These limited options address simpler on/off or three-way switching needs.

Switching Action

- Rotary Switches: Employ a rotating shaft or knob mechanism. This design allows for smooth transitions between multiple circuit configurations.

- Selector Switches: Employ a simpler rotary action, often limited to 2 or 3 fixed positions. Selector switch action provides a clear, unambiguous change between a limited number of states.

Contact Types

- Rotary Switches: Available in shorting and non-shorting contact configurations. Shorting types maintain continuity during switching, while non-shorting types break the circuit between positions.

- Selector Switches: Typically use either maintained or momentary contacts. Maintained contacts remain in place until manually changed, while momentary contacts return to the default position when released.

Number of Poles and Throws

- Rotary Switches: Typically have multiple poles and throws, allowing for complex switching arrangements. A single rotary switch can control multiple independent circuits simultaneously.

- Selector Switches: Typically have one pole and 2 or 3 throws. This simpler configuration is suitable for basic circuit selection or on/off control applications.

User Interface and Feedback

- Rotary Switches: Provide tactile feedback through detent or click sounds at each position. This feature allows the user to identify a specific setting without visual confirmation. Many rotary switches are labeled with positions for added clarity.

- Selector Switches: Provide clear visual indication of the selected position. Some models incorporate lighting to enhance visibility in low-light conditions.

Typical Applications

- Rotary Switches: Perform well in applications that require multiple settings or modes of operation. Common uses include multi-speed fan controls, radio band selection, and devices with various operating states.

- Selector Switches: Frequently used in simpler control scenarios. Typical applications include power tool trigger locks, audio output selection, and basic on/off or manual/auto mode selection in industrial controls.

How to Choose Between a Rotary and Selector Switch

1.Number of required switching positions

- Rotary switches excel in applications where multiple positions are required, often upwards of 10 or more. They provide versatility for complex circuit configurations and numerous setting options.

- Selector switches typically have 2 to 3 positions, making them suitable for simpler on/off or three-way switching needs. Consider the number of different operating states required when choosing these switch types.

2.Importance of tactile feedback and position indication

- Rotary switches provide tactile feedback through detents or clicks at each position. This feature allows the user to identify a specific setting without visual confirmation. Many rotary switches feature position labels for added clarity.

- Selector switches provide clear visual indication of the selected position, and some models incorporate lighting for enhanced visibility in low-light conditions. Evaluate the importance of tactile and visual feedback for your specific application.

3.Space constraints and required form factor

- Rotary switches typically have a compact design that allows multiple switching positions to be achieved in a limited space. They typically have a round contact arrangement.

- Selector switches are typically designed for panel mounting and may require more frontal space but less depth. Consider the available space and mounting requirements in your application when choosing between these switch types.

4.Complexity of Switching Applications

- Rotary switches can handle complex switching arrangements with multiple poles and throws. They are suitable for applications where multiple independent circuits need to be controlled simultaneously.

- Selector switches typically have a simpler configuration with a single pole and 2-3 throws. Evaluate the complexity of your switching needs to determine which type is better suited for your application.

5.Cost Considerations

- Because rotary switches have more complex internal mechanisms and are able to handle multiple positions, they can be more expensive than simple selector switches.

- Selector switches are simple in design and have limited positions and are generally more suitable for basic switching needs. Consider your budget constraints and the value of each switch type relative to your specific requirements.

Not sure which switch to choose?

Contact our technical team to obtain professional selection suggestions and quickly match your project requirements.

FAQs

1.What is the main difference between a rotary switch and a selector switch?

Rotary switches offer multiple positions (often 10+) and complex configurations, while selector switches typically have 2-3 positions for simpler on/off or limited-position control.

2.Which switch type provides more versatility?

Rotary switches offer greater versatility due to their multiple positions and ability to control various circuits simultaneously.

3.Are selector switches easier to use than rotary switches?

Generally, yes. Selector switches have fewer positions and provide clearer visual indication of the selected state, making them more user-friendly for simple applications.

4.Which switch type is better for applications requiring many operational modes?

Rotary switches are better suited for applications with numerous operational modes due to their ability to accommodate multiple positions.

5.Are selector switches or rotary switches more cost-effective?

Selector switches are usually more cost-effective due to their simpler design and limited positions.

6.Which switch type is preferred for industrial control panels?

Selector switches are commonly used in industrial control panels for their simple operation and clear position indication.

In Conclusion

Rotary and selector switches serve distinct purposes in electrical applications. Rotary switches offer versatility with multiple positions, while selector switches excel in simpler on/off control scenarios.

Choosing between them depends on the specific requirements of each project. Consider factors like position count, feedback type, and application complexity.

Select the right switch to optimize your electrical system’s performance and user experience.