Have you ever wondered how mechanical systems can automatically control electrical circuits? The answer lies in a simple yet ingenious device called a cam switch.

A cam switch is an electromechanical switch that uses a rotating cam to open and close electrical contacts. This unique design allows cam switches to convert mechanical motion into electrical switching, enabling precise control and timing of electrical circuits in a wide range of applications, from industrial machinery to household appliances.

What is a cam switch?

A cam switch is an electromechanical device that uses a rotating cam to actuate one or more sets of electrical contacts. The cam profile determines the sequence and duration of contact openings and closings. Cam switches are commonly used for controlling industrial equipment, machinery, and appliances.

These switches offer flexibility in designing complex switching sequences due to the customizable cam profiles. They are known for their robustness, reliability, and ability to handle high electrical loads. Cam switches find applications in various settings, including motor control, timer circuits, and process automation systems.

The contacts in a cam switch can be configured as normally open (NO), normally closed (NC), or a combination of both. As the cam rotates, it mechanically opens or closes these contacts based on the cam profile’s geometry. This allows cam switches to control multiple circuits simultaneously with a single rotating input.

Working Principle of a Cam Switch

A cam switch operates through the interaction between a cam and a follower mechanism. The cam typically mounted on a rotating shaft, features a contoured surface that directly controls the switch’s action.

As the cam rotates, its profile pushes against the follower, causing it to move according to the cam’s shape. This motion is then translated to the switch contacts, allowing them to open or close electrical circuits at predetermined positions.

The specific shape of the cam determines the timing and duration of the switch’s activation. Cam switches offer flexibility in designing complex switching sequences by utilizing cams with multiple lobes or varying profiles.

The follower, usually spring-loaded, maintains constant contact with the cam surface, ensuring precise and reliable switching action. This simple yet effective working principle enables cam switches to control various electrical functions based on the angular position of the rotating shaft.

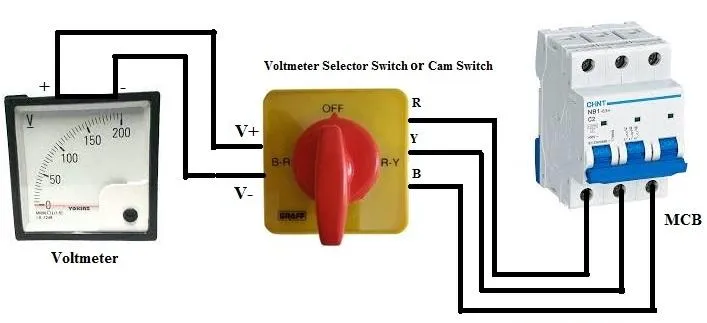

Wiring diagram of a cam switch

A typical cam switch wiring diagram shows multiple terminals corresponding to different switch positions. The diagram illustrates how circuits are connected or disconnected as the switch rotates.

For example, a voltmeter selector switch diagram may show connections for measuring voltages between different phases. The diagram indicates which terminals are active in each switch position.

Proper wiring ensures the cam switch performs its intended function, whether it’s isolating circuits, changing over power sources, or controlling motor operations.

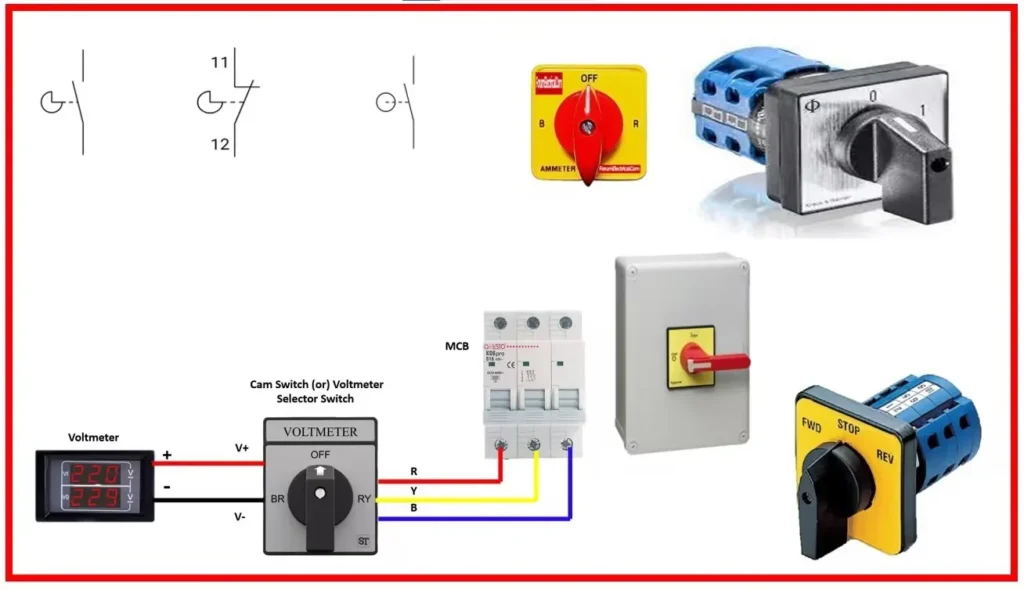

Types of cam switches

- Multistep Switches: These cam switches feature multiple positions, allowing for the sequential control of electrical circuits. They are commonly used in applications requiring step-by-step operations.

- Isolator Switches: Designed for safety purposes, isolator switches disconnect the electrical supply from a circuit. They ensure complete isolation during maintenance or repair work.

- Voltmeter Selector Switches: These cam switches enable the selection of different voltage measurement points in an electrical system. They are essential for monitoring and troubleshooting voltage levels.

- Changeover Switches: Also known as transfer switches, changeover switches allow the switching between two power sources. They are crucial for ensuring uninterrupted power supply in critical applications.

- Ammeter Selector Switches: Similar to voltmeter selector switches, ammeter selector switches facilitate the measurement of current at various points in an electrical circuit. They aid in monitoring and diagnosing current-related issues.

- Control Switches: These versatile cam switches are used for controlling various electrical devices and machines. They offer multiple positions and configurations to suit specific control requirements.

- Motor Control Switches: Specifically designed for motor control applications, these cam switches enable the starting, stopping, and reversing of electric motors. They ensure safe and reliable motor operation.

- Gang Switches: Gang switches combine multiple cam switches into a single unit, allowing for the simultaneous control of several circuits. They are space-saving solutions for complex electrical systems.

Applications

Cam switches find extensive use in various industrial and commercial settings. They are commonly employed for controlling electrical equipment such as motors, pumps, conveyors, and machine tools.

In HVAC systems, cam switches are utilized for managing fan speeds, temperature settings, and operational modes. They also play a crucial role in the automotive industry, being integrated into ignition systems, windshield wipers, and turn signal mechanisms.

Furthermore, cam switches are essential components in safety-critical applications like emergency stop buttons and limit switches in elevators and machinery. Their durability, reliability, and ability to handle high electrical loads make them indispensable in a wide range of electrical and mechanical systems.

Advantages and disadvantages of cam switches

Advantages

- Simple functionality and easy operation

- Compact size

- Low maintenance requirements

- Suitable for both AC and DC applications

- High level of IP protection

- Can be mounted on panel doors or enclosures

- Operates effectively in wide temperature ranges without derating

- Quick and easy installation

- Extremely long mechanical and electrical lifespan

- Versatile control capabilities for multiple circuits

- Precise and customizable switching sequences

- Durable construction for industrial environments

- Clear visual indication of switch position

Disadvantages

- Limited to physical operation (no remote control)

- Not suitable for extremely high current applications

- Lack of built-in protection against magnetic and thermal currents

- Require manual rotational force to activate

- More complex and potentially more expensive than simple switches

- May experience mechanical wear over time

- Limited by the practical number of positions they can handle

- Require precise manufacturing and assembly

FAQs

Can cam switches be used for both AC and DC applications?

Yes, cam switches are suitable for both AC and DC applications, making them versatile for various electrical control needs.

How do cam switches compare to other types of switches?

Cam switches offer more complex control capabilities than simple switches but are manually operated. They’re more durable and versatile than toggle switches but less flexible than programmable switches.

What factors should be considered when selecting a cam switch?

Consider the number of switch positions, voltage rating, number of contacts and poles, durability requirements, precision needs, and suitability for the specific application.

Are cam switches suitable for high-current applications?

Cam switches are generally not suitable for extremely high current applications. They’re typically used for control circuits rather than high-power switching.

In Conclusion

Cam switches offer versatile and reliable control for multiple electrical circuits in various industrial applications. Their compact design, durability, and precise operation make them valuable components in many control systems.

Consider cam switches for your next electrical control project. Consult with a qualified electrician to determine if they suit your specific requirements.