جدول المحتويات

ما هو مفتاح الزر الضاغط؟

A push button switch is a basic electrical part used to start, stop, or control actions in a system. It is widely used in everyday settings, from homes and offices to outdoor equipment. You may also hear it called a pushbutton switch or simply a push switch. Despite its simple design, it plays an important role in how people interact with devices.

These switches are usually made from strong materials such as plastic or metal. The button surface can be flat or shaped to fit the finger for easier use. When pressed, the switch works through a simple electrical or air-based mechanism to open or close a circuit, making it easy to turn devices on or off.

Push button switches generally fall into two main types based on how they work: momentary and latching.

Momentary switches only stay active while you are pressing them. Once you let go, the circuit breaks.

Latching switches stay in their current position after being pressed and change state only when pressed again.

Because of this flexibility, push button switches are used in many fields. They control household appliances, electronic devices, and even large industrial machines.

How Does a Push Button Switch Work?

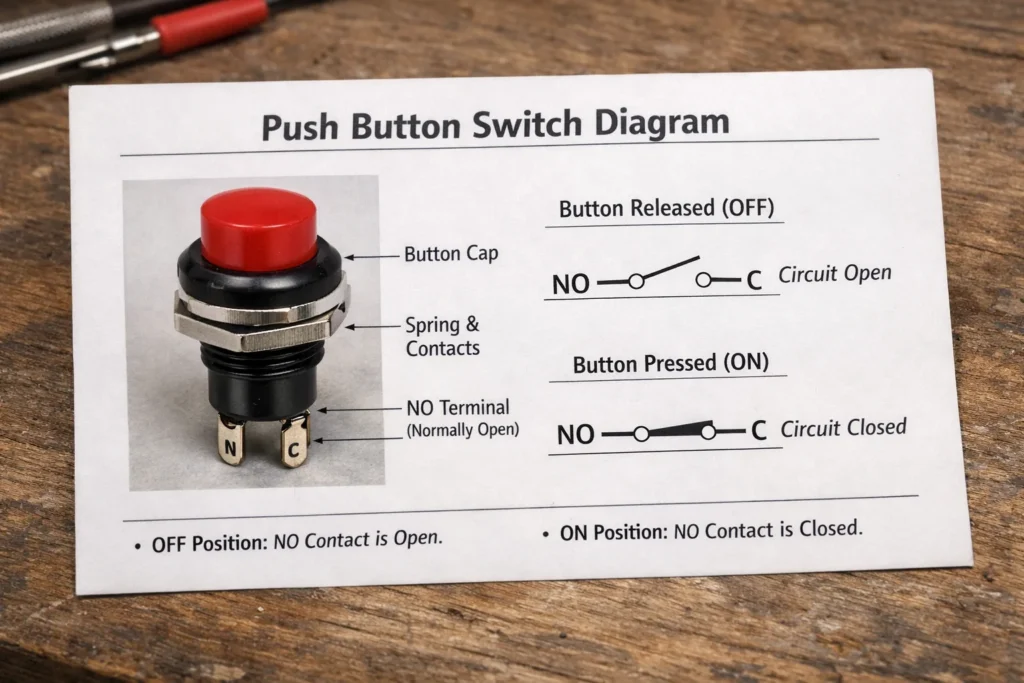

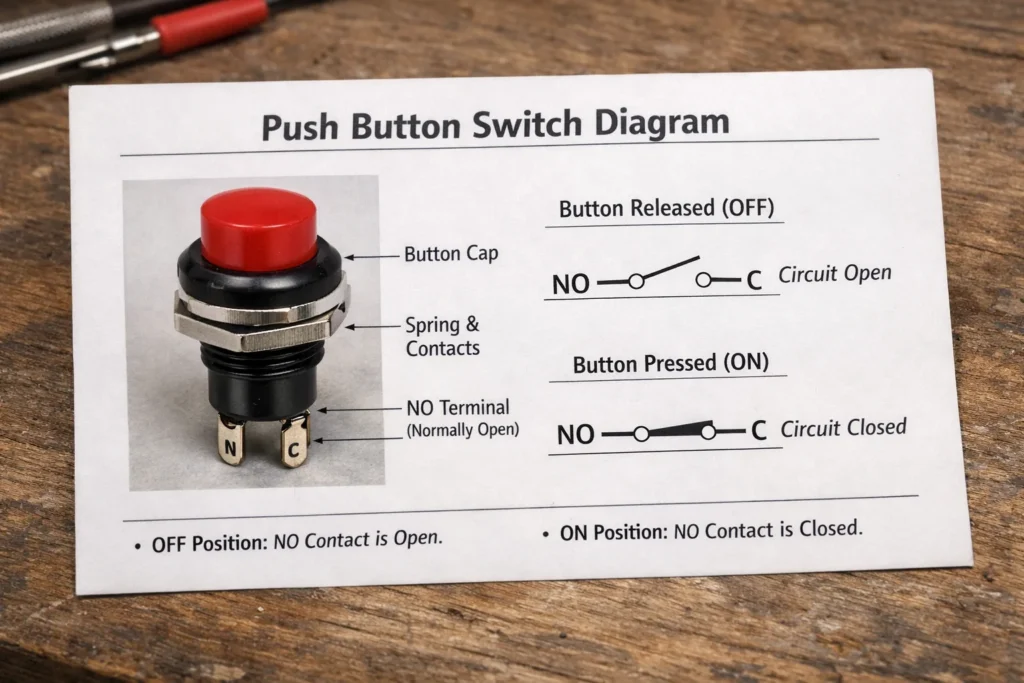

Most push button switches work in a simple and reliable way. When you press the button, also called the actuator, it pushes against a spring inside the switch. This movement brings the internal contacts together or pulls them apart. As a result, the electrical circuit is either completed or broken, allowing current to flow or stopping it. When the pressure is released, the spring returns to its original position, changing the switch back or preparing it for the next press.

Push button switches are available with two common contact types, depending on how the circuit behaves.

Normally open (NO) switches stay off until the button is pressed, which completes the circuit.

Normally closed (NC) switches stay on by default and break the circuit when the button is pressed.

Because of these options, push button switches can be used in many situations. They appear in everyday products such as elevators and remote controls, and they also play a key role in safety systems and industrial equipment where dependable control is essential.

Push Button Switch Diagram

The diagram shows how a push button switch fits into an ignition circuit and how it supports quick starting. It highlights the switch’s position within the circuit and explains how pressing the button completes the connection. The layout makes it easy to understand the wiring path and the basic structure needed for the switch to work correctly in practical use.

Push Button Switch Applications

Push button switches are widely used because they are simple, reliable, and easy to operate. They help control electrical circuits in many settings, from everyday home devices to advanced industrial systems. You can find them in products such as calculators, push-button phones, and many household or office appliances. Their main tasks include turning equipment on or off and triggering specific actions, like entering numbers on a keypad.

To improve safety and ease of use, many push button switches use color markings. Red buttons usually signal a stop function, while green buttons are often used to start a process. Emergency stop buttons are commonly large and red, making them easy to spot and press quickly when needed.

Thanks to their flexibility, push button switches appear in a wide range of applications:

- Reset switches: Often small and recessed, these switches are pressed with a tool to reset devices or systems.

- Machinery control: In factories, clearly marked buttons are placed on or near machines to allow fast shutdown during emergencies.

- الأجهزة المنزلية: Devices such as washing machines, microwaves, and dishwashers use push buttons to control different functions.

- Automotive use: Many vehicles rely on push buttons for engine start, lighting, and window controls.

- Medical equipment: Hospitals and clinics use push button switches in machines like infusion pumps and testing devices for accurate operation.

- Security systems: These switches help arm or disarm alarms, manage access points, and activate emergency signals.

- Lifts and escalators: Push buttons are essential for floor selection and smooth operation in public and private buildings.

Push Button Switch Types

Push button switches come in many forms, each designed for a specific use. Choosing the right type matters. The decision usually depends on how the switch will be used, the button design, and the level of protection needed against dust or water.

Below are common push button switch types and what makes each one useful.

Momentary Push Buttons

Momentary switches only work while the button is pressed. Once released, the circuit stops. They are ideal for short actions, such as doorbells, alarms, or car starters. In diagrams, symbols often show this temporary action and the number of connected circuits.

Arduino Push Buttons

These buttons are made for use with Arduino boards. They allow easy control of electronic projects and prototypes. Thanks to strong community support, they are widely used in learning, testing, and hobby electronics.

2-Position Push Button Switches

These switches have two fixed states: on and off. Some models are protected with plastic housings or require a key, making them suitable for controlled or secure environments.

Dual Push Button Switches

Dual switches use two buttons instead of one. One button starts an action, often green. The other stops it, usually red. Many versions include LED lights to show the current status clearly.

Miniature Push Button Switches

Mini or micro switches are small and fit into tight spaces. They are often used for reset functions or quick commands in compact electronic devices.

Push to Break Switches (Normally Closed)

In normally closed switches, current flows until the button is pressed. Pressing the button stops the circuit. This design is common in emergency stop systems where power must cut off instantly.

Push to Make Switches (Normally Open)

Normally open switches only allow current to pass when pressed. Releasing the button breaks the circuit. They are often used in calculators and doorbells. Some models combine both open and closed functions.

Square Push Button Switches

Square-shaped buttons come in many colors and sizes. Their shape makes them easy to press, which is why they are popular in industrial machines and automated systems.

Circuit Board Push Button Switches

These switches mount directly onto printed circuit boards. They are widely used in keyboards, keypads, and control panels where space and accuracy matter.

Tactile Push Button Switches

Also called tact switches, these require little force to press and give a clear click as feedback. Some include LED lights to show operation status or signal faults.

Panel Mounted Push Button Switches

Panel-mounted switches are designed for firm installation. They require precise cut-out sizes based on technical drawings and are common in both home and industrial equipment.

Latching Push Button Switches

Latching switches stay on or off until pressed again. They are often used for power buttons and light controls where a steady state is needed.

Locking Push Button Switches

These switches lock after being pressed and must be pressed again to release. This feature helps prevent accidental use and was common in older electronic devices.

Industrial Push Buttons

Industrial push buttons are built for harsh environments. They include strong housings and simple installation parts, making them suitable for safely controlling heavy machinery.

Push to Make Door Switches

These surface-mounted switches are used on doors to trigger electrical actions. Made from durable materials, they work well with sliding or standard doors in many settings.

| Push Button Switch Type | What It Does | الاستخدامات الشائعة | Main Benefit |

|---|---|---|---|

| Momentary Push Button | Works only while pressed | Doorbells, alarms | Simple and quick control |

| Arduino Push Button | Sends input to Arduino boards | DIY projects, learning kits | Easy to use for beginners |

| 2-Position Push Button | Stays on or off | Secure controls, machines | Clear on/off control |

| Dual Push Button Switch | One button starts, one stops | Industrial equipment | Reduces operating mistakes |

| Miniature Push Button | Fits in small devices | Reset buttons, electronics | Saves space |

| اضغط لكسر المفتاح | Stops power when pressed | Emergency stop systems | Improves safety |

| اضغط لإجراء التبديل | Turns on power when pressed | Calculators, doorbells | Reliable short action |

| Square Push Button Switch | Easy-to-press shape | Industrial machines | Comfortable to use |

| Circuit Board Push Button | Built into circuit boards | Keyboards, control panels | Compact and precise |

| Tactile Push Button Switch | Clicks when pressed | Electronics, indicators | Clear press feedback |

| Panel Mounted Push Button | Installed on panels | Appliances, control boxes | Easy access |

| Latching Push Button | Stays on until pressed again | Power and light switches | Convenient control |

| Locking Push Button | Locks after pressing | Older electronics | Prevents accidental use |

| Industrial Push Button | Handles tough conditions | Heavy machinery | Strong and durable |

| Push to Make Door Switch | Activates door functions | Sliding or standard doors | Simple door control |

Push Button Switch Voltage Ratings

When choosing a push button switch, it is not enough to look only at the current rating. Even if the current seems safe, the switch may still be unsuitable. Voltage rating is a key factor, and it differs between AC and DC systems. Knowing this difference helps prevent failure and safety risks.

Push button switches are usually rated for specific voltage ranges, often from 24V up to 250V in both AC and DC use. For example, a switch marked for 24V DC should only be used in circuits that stay within that limit. Using it at a higher voltage can damage the switch or create unsafe conditions.

AC and DC ratings are not interchangeable. In AC circuits, the voltage naturally drops to zero during each cycle. This helps stop arcing when the switch opens. DC circuits behave differently. The current flows in one direction without a natural break, which makes arcing harder to stop. Over time, this can cause burned contacts, heat buildup, and early failure.

The type of load also matters when selecting a switch. Push button switches react differently depending on what they control.

Inductive loads such as motors or transformers often draw a high surge of current when they start. This sudden increase can create voltage spikes when the circuit opens, putting extra stress on the switch.

Resistive loads like heaters or standard light bulbs reach normal current levels right away. They produce little or no surge, which makes them easier for switches to handle.

Taking voltage type and load characteristics into account ensures the push button switch will work safely and last longer in its intended application.

Choosing the Right Type of Push Button Switch

Selecting the right push button switch means matching the switch to how and where it will be used. Several factors should be reviewed to ensure reliable performance and safe operation.

1. Application requirements

Start by defining the switch’s main role. Decide whether the action needs to be momentary, such as starting a machine, or latching, like turning a light on and off. The type of load is also important. Resistive loads, such as heaters, are easier to manage. Inductive loads, including motors, create higher surge currents and require switches rated to handle that stress.

2. Actuator style

Push buttons are available in many shapes and sizes, including round, square, and rectangular designs. Choose a size that fits the available space and feels comfortable to use. Some switches include built-in lighting to show on or off status, which can be helpful in dark or busy environments.

3. Environmental conditions

Consider where the switch will operate. In outdoor or industrial areas, a higher IP rating is important to protect against dust and moisture. Temperature also matters, as some switches must perform reliably in very hot or very cold conditions.

4. Mounting options

Decide how the switch will be installed. Panel-mounted switches are easy to reach and commonly used for user controls. PCB-mounted switches are smaller and suited for compact electronic designs.

5. Safety features

In industrial settings, safety is critical. Emergency stop push buttons are designed for fast access and usually have larger, clearly visible actuators. These features help ensure quick response during dangerous situations.

By reviewing these points, you can choose a push button switch that fits your application, environment, and safety needs.

الأسئلة الشائعة

What is a push button switch?

A push button switch is an electrical control device used to manage the flow of power in a circuit. It works by pressing a button, which changes the circuit state either temporarily or until the button is pressed again.

How do I choose the right push button switch for my application?

Start by matching the switch’s voltage and current ratings to your circuit. Then consider the load type, whether resistive or inductive, as inductive loads need stronger ratings. You should also think about where the switch will be used and select a suitable IP rating for dust or water protection. Finally, choose a mounting style, such as panel-mounted or PCB-mounted, based on your design.

What should I do if my push button switch is not working?

First, check that the power supply is active. Then look for loose wires, poor connections, or visible damage. Dust or dirt may also prevent proper operation, so cleaning the switch can help. If the switch shows signs of wear or still does not work, replacing it is usually the best option.

What safety measures should I follow when using push button switches?

Always disconnect power before installing or servicing a switch. Make sure the switch is rated for the correct voltage and current to avoid overheating or failure. In higher-power systems, adding protective devices such as fuses can improve overall safety.

Can push button switches be used outdoors?

Yes, but only if they are designed for outdoor use. Choose switches with adequate IP ratings to protect against water, dust, and other environmental factors. Sealed designs are usually best for these conditions.

How do I install a push button switch?

Begin by turning off power to the circuit. Choose a proper mounting location and prepare the opening if needed. Connect the wires according to the datasheet instructions. Secure the switch firmly, then restore power and test its operation. For complex systems, professional installation is recommended.