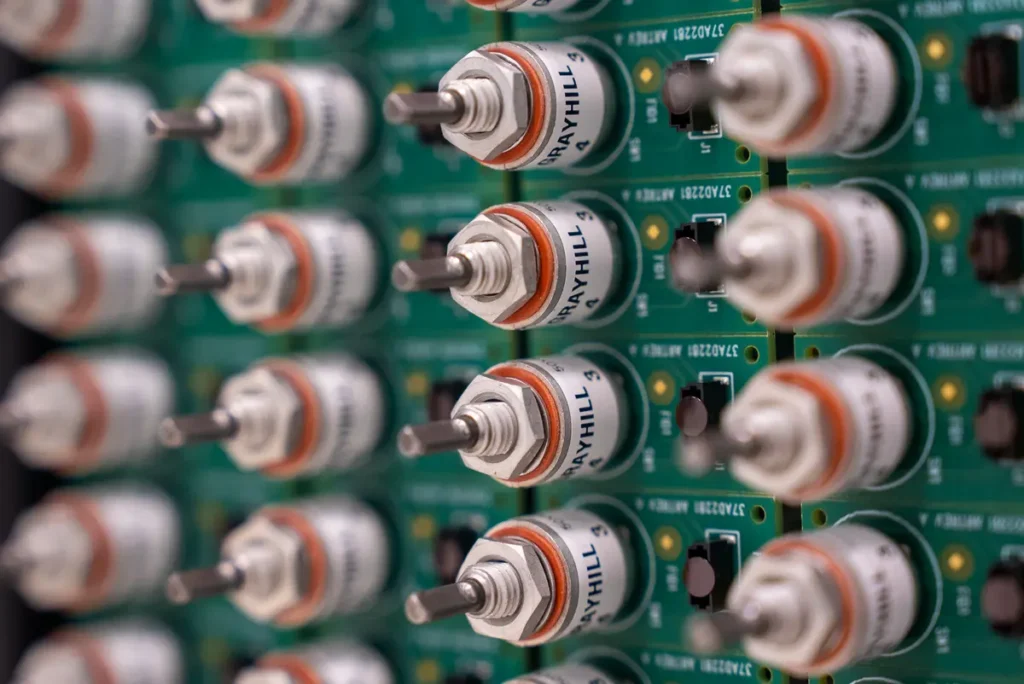

The discussion in this blog centers on 3-position and 4-position rotary switches, alongside key considerations for partnering with providers who prioritize quality and adhere to industry standards.

For manufacturers operating in sectors like vehicle solutions, military applications, and healthcare equipment, the choice between a 3-position and 4-position rotary switch extends beyond simply adding an extra setting. It directly impacts the usability, functionality, and integration of the systems these switches control. For OEM manufacturers and parts makers, grasping these distinctions is essential to developing products that not only meet but surpass industry standards.

This exploration into the intricacies of rotary switches highlights the significance of informed decision-making and the value of collaborating with experts to achieve superior outcomes for complex systems. By understanding the unique demands of each application and leveraging the right switch solutions, manufacturers can deliver innovative, reliable, and user-friendly products tailored to their industries’ evolving needs.

3 and 4-Position Rotary Switch the Technical Distinction

A 3-position rotary switch enables users to cycle through three distinct operational modes or electrical circuits. This design strikes a balance between flexibility and simplicity, making it ideal for systems that demand straightforward control without overwhelming options.

In contrast, a 4-position rotary switch introduces a fourth configuration, expanding its utility for scenarios requiring layered functionality or coordination of multiple processes. The added position enhances adaptability, catering to setups where precision or integration of varied functions within a single interface is critical.

While the 3-position version suits basic modular needs, the 4-position variant excels in environments where incremental adjustments or multifunctional operation are priorities.

Key Differences

- Complexity and Control: A 4-position switch inherently accommodates more intricate operational frameworks, allowing for precise and nuanced control over a device’s functionalities. This added layer of control is particularly beneficial in systems requiring multiple operational modes or fine-tuned adjustments.

- Circuit Design: Incorporating an additional position influences the internal circuit design, often leading to increased complexity or a larger physical footprint. This trade-off must be carefully considered to balance functionality with practical design constraints.

- Customization Potential: The extra positions in a 4-position switch expand its adaptability, enabling tailored configurations to meet specific application needs. This customization enhances the user experience, making the switch a versatile solution for specialized requirements.

Industries and Applications

- Vehicle Solutions: In the automotive sector, 4-position switches provide enhanced control over vehicle performance and comfort features. For example, they can manage driving modes—such as economy, standard, sport, and custom—or adjust interior lighting settings, including off, dim, bright, and auto. This versatility allows drivers to personalize their experience based on specific needs or preferences.

- Military Applications: Military equipment relies on precision and adaptability, making 4-position rotary switches a critical component. These switches enable seamless transitions between communication channels or operational modes, such as secure, encrypted, open, and off. Such functionality ensures reliability and effectiveness in high-stakes defense scenarios.

- Healthcare Equipment: In healthcare, 4-position switches are integral to the operation of medical devices. They facilitate adjustments like power levels (off, low, medium, high) or operational modes (scan, diagnose, treat, and off), depending on the device’s purpose. This flexibility ensures medical professionals can optimize equipment performance to deliver effective patient care.

The Role of a Quality-Oriented Provider

A quality-focused provider, backed by extensive experience and expertise, is essential in delivering the ideal switch solution. They recognize that every industry and application presents distinct demands and challenges. Leveraging their knowledge, they not only recommend the most suitable rotary switch but also design and integrate these components into holistic systems. Such providers excel in offering:

- Custom-Designed Solutions: They craft switches with tailored functionality and haptics, ensuring they align precisely with application-specific needs. This customization enhances usability and delivers a seamless, intuitive user experience.

- Technical Consultation: Providers guide clients through the selection process, taking into account critical factors such as environmental conditions, operational demands, and durability. Their insights help clients make informed decisions that optimize performance and longevity.

- Integrated Interfaces: By designing solutions that effortlessly integrate into existing systems, they enhance both functionality and aesthetic appeal. This seamless integration ensures that the switches not only perform well but also complement the overall design of the equipment or device.

A Summary

Selecting between a 3-position and a 4-position rotary switch requires weighing factors like complexity, control, and customization. For industries such as automotive, military, and healthcare, this choice directly influences the functionality and user experience of essential systems.

Collaborating with a quality-oriented supplier goes beyond simply providing a switch—it ensures a fully integrated interface solution. These solutions are meticulously custom-designed, combining technical precision with a human-centric approach that elevates them above standard offerings. It is this blend of advanced engineering and thoughtful design that drives innovation and effectiveness in today’s cutting-edge manufacturing landscape.

Rotary Switch: Operator Interface Products

The manufacturing sector, particularly in the realm of standard operator interface products, is increasingly shaped by significant investments in Research and Development (R&D). Leading companies in this field adopt a holistic approach to innovation, combining in-house design expertise with robust supply chain management to produce products that redefine quality, functionality, and user experience. Key capabilities and competencies essential for maintaining a competitive edge include:

- Investment in R&D: At the heart of innovation, R&D drives the exploration of new ideas, materials, and technologies. It enables the creation of cutting-edge products that push the boundaries of operator interface technologies.

- Industrial Design: This discipline focuses on designing products that are both functional and visually appealing. It ensures that operator interfaces are not only effective but also enhance the overall user experience.

- Ergonomics: Ergonomic design prioritizes user comfort and efficiency, reducing fatigue and boosting productivity. This is especially important for applications involving prolonged use.

- Mechanical Engineering: Mechanical engineers ensure the durability and reliability of products by designing components that work seamlessly within the broader system.

- Electrical Engineering: This field involves the development of electronic circuits and systems that power operator interfaces. It encompasses both hardware and firmware design to ensure high performance and dependability.

- Software Engineering: Software engineers create intuitive and seamless user interfaces, enabling smooth interaction between users and the product.

- Test Engineering: Rigorous testing ensures products meet strict quality standards, identifying and resolving potential issues before they reach the market.

- Manufacturing Engineering: This discipline focuses on optimizing production processes to ensure efficient, high-quality manufacturing while minimizing waste.

- Supplier Quality Engineering: Managing and vetting suppliers is crucial to ensure all components meet quality standards, safeguarding the integrity of the final product.

- Process Quality Engineering: Continuous improvement of manufacturing processes ensures consistent product quality and reduces variability in production.

- Reliability Engineering: This ensures products are durable and perform consistently over time, fostering customer trust and satisfaction.

Conclusion

A robust competency framework is critical for designing and delivering top-tier standard operator interface products that excel in quality, functionality, and user experience.

At Cantak, our commitment to R&D, paired with deep expertise across multiple engineering disciplines, drives innovation and enables us to create solutions that adapt to the ever-changing demands of diverse industries.

By integrating cutting-edge technology with a user-centric approach, we ensure our products not only meet but exceed expectations, setting new benchmarks in the field.